AMS-CB and AMS-H, two series of marker, the heat shrikable sleeves are designed to meet the cable and wire marking needs of manufacturers with high performance requirements. Made from permanent, flame retarded, radiation cross-linked shrinkable polyolefin.

AMS-CB and AMS-H marker are the military grade wire identification sleeves: meet the requirements of AMS-DTL-23053/5 classes 1 and 3.

Either AMS-CB or AMS-H has two expansion ratios, both 2:1 and 3:1 shrink ratios are available, see table 1 to table 4.

AMS-CB and AMS-H are permanent immediately after printing and remain legible even when exposed to abrasion, agressive cleaning solvents and military fuels and oils.

The sleeves meet the mark permanent requirements of SAE AS 81531 before and after shrinking. The 2:1 products provide a thick, rugged sleeve wall and are particularly easy to handle. The lightweight 3:1 products provide extremely fast shrinking and cover a wider range of wire diameters, thus simplifying inventory.

The marker sleeves are designed to be printed by computer-driven heavy duty dot matrix. thermal transfer printers and laser graver printers providing several advantages in terms of reduced error, cycle time and cost.

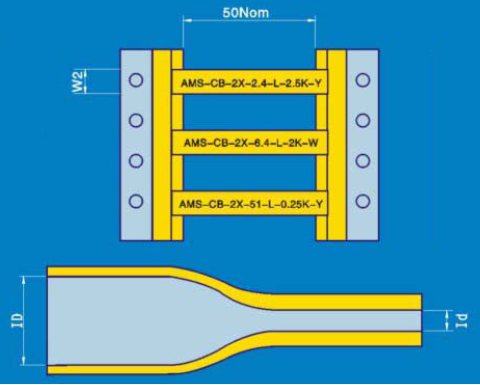

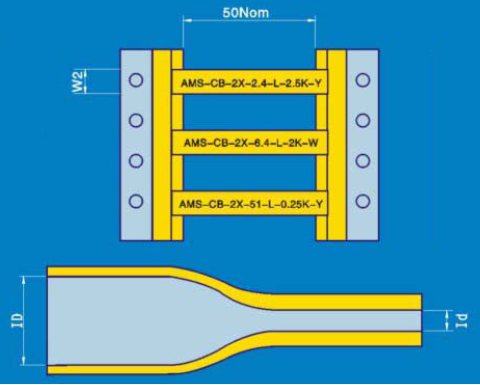

Supplied in a thin, flatten "cartridge belt" format, the sleeves are held horizontally between two hole-punched polyester strips. This configuration feeds directly from the storage box into a recommended Wolabel printer, Wolabel ribbons should always be used. The "cartridge belt" format provides automatic kitting of marker sleeves in the desired sequence. A standard heat gun with reflector is used to shrink the sleeves onto the wire or cable.

Characteristics

-

Permanent identification sleeves

-

Computer-printable

-

Lightweight for aerospace applications

-

Military grade material and high print performance

-

2:1 and 3:1 shrink ratio

-

Flame retarded, VW-1

-

Temperature rating +135oC / 275 oF

-

Quick recovery for heat sensitive areas

-

RoHS compliant

|

Operating temperature range -55 oC to +135 oC

-67oF to +275 oF

Minimum recovery temperature: +85 oC / +185 oF

Maximum storage temperature: +50 oC / +122 oF

Totally shrink temperature: +85 oC / +185 oF

Military AMS-DTL-23053/5 classes 1 and 3

SAE AS 81531, MIL-STD-202F Method 215J

Wolabel recommeded printer:

WO-III 110-600 (thermal printer)

WO-III 110-300 (thermal printer)

WO-III 140-203 (thermal printer)

WO-III 170-300 (thermal printer)

WO-III 220-203 (thermal printer)

WO-6310 (dot matrix)

WO-9200 (laser grave)

Wolabel ribbon:

WO-10345BK (thermal transfer)

WO-2427BK (thermal transfer)

WO-1892BK04 (dot matrix)

WO-1K (air heat)

WO-2K (air heat)

WO-3K (air heat)

WO-0K (butane, micro-flame)

|

PART NUMBERING SYSTEM

Table 1 - Sizes for 2X Super-Thin Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-CB-2X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.35 ± 0.10 |

≤ 1.18 |

0.36 ± 0.06 |

|

AMS-CB-2X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.36 ± 0.10 |

≤ 1.59 |

0.37 ± 0.06 |

|

AMS-CB-2X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.36 ± 0.10 |

≤ 2.36 |

0.37 ± 0.06 |

|

AMS-CB-2X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.37 ± 0.10 |

≤ 3.18 |

0.38 ± 0.06 |

|

AMS-CB-2X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.38 ± 0.11 |

≤ 4.75 |

0.39 ± 0.06 |

|

AMS-CB-2X-12.7-*-1k-* |

12.7 ± 0.36 |

19.9 ± 0.6 |

0.38 ± 0.11 |

≤ 6.35 |

0.39 ± 0.07 |

|

AMS-CB-2X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.40 ± 0.11 |

≤ 9.53 |

0.40 ± 0.07 |

|

AMS-CB-2X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.40 ± 0.12 |

≤ 12.7 |

0.41 ± 0.07 |

|

AMS-CB-2X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.42 ± 0.12 |

≤ 19.1 |

0.42 ± 0.07 |

|

AMS-CB-2X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.43 ± 0.13 |

≤ 25.4 |

0.43 ± 0.08 |

|

AMS-CB-2X-76-*-0.25k-* |

76.2 ± 0.63 |

119.7 ± 1.0 |

0.44 ± 0.14 |

≤ 38.1 |

0.45 ± 0.08 |

Dimensions tables 1 and 2

Table 2 - Sizes for 2X Normal Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-H-2X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.62 ± 0.10 |

≤ 1.18 |

0.64 ± 0.06 |

|

AMS-H-2X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.63 ± 0.10 |

≤ 1.59 |

0.64 ± 0.06 |

|

AMS-H-2X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.64 ± 0.10 |

≤ 2.36 |

0.65 ± 0.06 |

|

AMS-H-2X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.65 ± 0.10 |

≤ 3.18 |

0.66 ± 0.06 |

|

AMS-H-2X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.67 ± 0.11 |

≤ 4.75 |

0.68 ± 0.06 |

|

AMS-H-2X-12.7-*-1k-* |

12.7 ± 0.36 |

19.9 ± 0.6 |

0.68 ± 0.11 |

≤ 6.35 |

0.69 ± 0.07 |

|

AMS-H-2X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.69 ± 0.11 |

≤ 9.53 |

0.71 ± 0.07 |

|

AMS-H-2X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.71 ± 0.12 |

≤ 12.7 |

0.72 ± 0.07 |

|

AMS-H-2X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.73 ± 0.12 |

≤ 19.1 |

0.74 ± 0.07 |

|

AMS-H-2X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.75 ± 0.13 |

≤ 25.4 |

0.76 ± 0.08 |

|

AMS-H-2X-76-*-0.25k-* |

76.2 ± 0.63 |

119.7 ± 1.0 |

0.78 ± 0.14 |

≤ 38.1 |

0.79 ± 0.08 |

Table 3 - Sizes for 3X Super-Thin Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-CB-3X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.36 ± 0.10 |

≤ 0.79 |

0.56 ± 0.06 |

|

AMS-CB-3X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.36 ± 0.10 |

≤ 1.06 |

0.56 ± 0.06 |

|

AMS-CB-3X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.37 ± 0.10 |

≤ 1.59 |

0.57 ± 0.06 |

|

AMS-CB-3X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.38 ± 0.10 |

≤ 2.36 |

0.58 ± 0.06 |

|

AMS-CB-3X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.39 ± 0.11 |

≤ 3.18 |

0.60 ± 0.06 |

|

AMS-CB-3X-12.7-*-1k-* |

12.7 ± 0.35 |

19.9 ± 0.6 |

0.39 ± 0.11 |

≤ 4.75 |

0.61 ± 0.07 |

|

AMS-CB-3X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.40 ± 0.11 |

≤ 6.35 |

0.63 ± 0.07 |

|

AMS-CB-3X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.42 ± 0.12 |

≤ 8.47 |

0.64 ± 0.07 |

|

AMS-CB-3X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.43 ± 0.12 |

≤ 19.1 |

0.42 ± 0.07 |

|

AMS-CB-3X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.43 ± 0.13 |

≤12.7 |

0.68 ± 0.08 |

|

AMS-CB-3X-76-*-0.25k-* |

76.2 ± 0.64 |

119.7 ± 1.0 |

0.48 ± 0.14 |

≤ 25.4 |

0.71 ± 0.08 |

Dimensionas for tables 3 and 4

Table 4 - Sizes for 3X Normal Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-H-3X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.44 ± 0.10 |

≤ 0.79 |

0.68 ± 0.06 |

|

AMS-H-3X-3.2-*-2.5k-* |

3.18 ± 0.22 |

5.0 ± 0.4 |

0.44 ± 0.10 |

≤ 1.06 |

0.68 ± 0.06 |

|

AMS-H-3X-4.8-*-2k-* |

4.75 ± 0.26 |

7.5 ± 0.4 |

0.45 ± 0.10 |

≤ 1.59 |

0.69 ± 0.06 |

|

AMS-H-3X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.46 ± 0.10 |

≤ 2.36 |

0.70 ± 0.06 |

|

AMS-H-3X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.46 ± 0.11 |

≤ 3.18 |

0.72 ± 0.06 |

|

AMS-H-3X-12.7-*-1k-* |

12.7 ± 0.35 |

19.9 ± 0.6 |

0.47 ± 0.11 |

≤ 4.75 |

0.73 ± 0.07 |

|

AMS-H-3X-19-*-1k-* |

19.1 ± 0.41 |

30.0 ± 0.6 |

0.48 ± 0.11 |

≤ 6.35 |

0.75 ± 0.07 |

|

AMS-H-3X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.49 ± 0.12 |

≤ 8.47 |

0.76 ± 0.07 |

|

AMS-H-3X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.51 ± 0.12 |

≤ 12.7 |

0.78 ± 0.07 |

|

AMS-H-3X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.52 ± 0.13 |

≤ 16.9 |

0.80 ± 0.08 |

|

AMS-H-3X-76-*-0.25k-* |

76.2 ± 0.64 |

119.7 ± 1.0 |

0.54 ± 0.14 |

≤ 25.4 |

0.83 ± 0.08 |