RSFR-CB and RSFR-H, two series of halogen free identification sleeves are designed to meet the cable and wire marking needos of manufacturers with high performance requirements. Made from permanent, flame retarded, radiation cross-linked shrinkable poliolefin.

RSFR-CB and RSFR-H meet the requirements of UL 224.

Either RSFR-CB or RSFR-H has two expansion ratios, both 2:1 and 3:1 shrink ratios are available, see table 1 to table 4.

RSFR-CB and RSFR-H are permanent immediately after printing and remain legible even when exposed to abrasion or agressive cleaning solvents.

The 2:1 products provide a thick, rugged sleeve wall and are particularly easy to handle. The lightweight 3:1 products provide extremely fast shrinking and cover a wider range of wire diameters, thus simplifying inventory.

The marker sleeves are designed to be printed by computer-driven heavy duty dot matrix. thermal transfer printers and laser graver printers, providing several advantages in terms of reduced error, cycle time and cost.

Supplied in a thin, flatten "cartridge belt" format, the sleeves are held horizontally between two hole-punched polyester strips. This configuration feeds directly from the storage box into a recommended Wolabel printer, Wolabel ribbons should always be used. The "cartridge belt" format provides automatic kitting of marker sleeves in the desired sequence. A standard heat gun with reflector is used to shrink the sleeves onto the wire or cable.

RSFR-CB and RSFR-H are the HFEF materias, comply with the requirements of RoHS, IEC 61249-2-21, 2002/72/EC, Japan Toy Safety Standard Part 3 and SS00259.

Characteristics

-

Permanent identification sleeves

-

Computer-printable

-

2:1 and 3:1 shrink ratio

-

CSA certified

-

UL reconigzed, VW-1 and all flame tubing test rated

-

Quick recovery for heat sensitive areas

-

Not only RoHS compliant, but also halogen free

|

Operating temperature range -55 oC to +125 oC

-67oF to +257 oF

Minimum recovery temperature: +85 oC / +185 oF

Totally shrink temperature: +115 oC / + 239 oF

Maximum storage temperature: +50 oC / +122 oF

UL 224 Reconigzed file E203850

CSA Certified File 220127

Wolabel recommeded printer:

WO-III 110-600 (thermal printer)

WO-III 110-300 (thermal printer)

WO-III 140-203 (thermal printer)

WO-III 170-300 (thermal printer)

WO-III 220-203 (thermal printer)

WO-6310 (dot matrix)

WO-9200 (laser grave)

Wolabel ribbon:

WO-5095BK10245 (thermal transfer)

WO-AXR7 (thermal transfer)

WO-1892BK04 (dot matrix)

WO-1K (air heat)

WO-2K (air heat)

WO-3K (air heat)

WO-0K (butane, micro-flame)

|

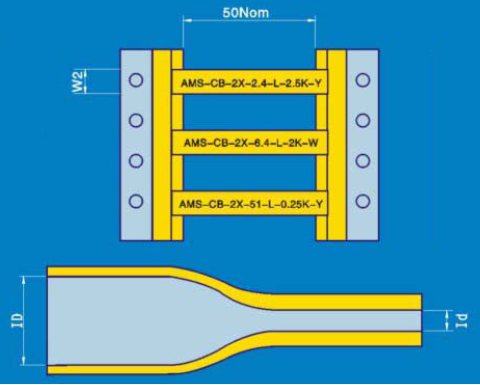

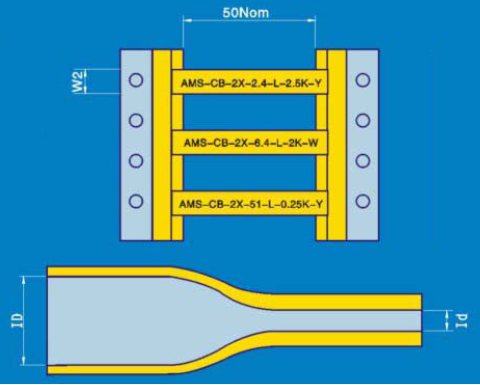

PART NUMBERING SYSTEM

Table 1 - Sizes for 2X Super-Thin Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-CB-2X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.35 ± 0.10 |

≤ 1.18 |

0.36 ± 0.06 |

|

AMS-CB-2X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.36 ± 0.10 |

≤ 1.59 |

0.37 ± 0.06 |

|

AMS-CB-2X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.36 ± 0.10 |

≤ 2.36 |

0.37 ± 0.06 |

|

AMS-CB-2X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.37 ± 0.10 |

≤ 3.18 |

0.38 ± 0.06 |

|

AMS-CB-2X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.38 ± 0.11 |

≤ 4.75 |

0.39 ± 0.06 |

|

AMS-CB-2X-12.7-*-1k-* |

12.7 ± 0.36 |

19.9 ± 0.6 |

0.38 ± 0.11 |

≤ 6.35 |

0.39 ± 0.07 |

|

AMS-CB-2X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.40 ± 0.11 |

≤ 9.53 |

0.40 ± 0.07 |

|

AMS-CB-2X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.40 ± 0.12 |

≤ 12.7 |

0.41 ± 0.07 |

|

AMS-CB-2X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.42 ± 0.12 |

≤ 19.1 |

0.42 ± 0.07 |

|

AMS-CB-2X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.43 ± 0.13 |

≤ 25.4 |

0.43 ± 0.08 |

|

AMS-CB-2X-76-*-0.25k-* |

76.2 ± 0.63 |

119.7 ± 1.0 |

0.44 ± 0.14 |

≤ 38.1 |

0.45 ± 0.08 |

Dimensions for tables 1 and 2

Table 2 - Sizes for 2X Normal Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-H-2X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.62 ± 0.10 |

≤ 1.18 |

0.64 ± 0.06 |

|

AMS-H-2X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.63 ± 0.10 |

≤ 1.59 |

0.64 ± 0.06 |

|

AMS-H-2X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.64 ± 0.10 |

≤ 2.36 |

0.65 ± 0.06 |

|

AMS-H-2X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.65 ± 0.10 |

≤ 3.18 |

0.66 ± 0.06 |

|

AMS-H-2X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.67 ± 0.11 |

≤ 4.75 |

0.68 ± 0.06 |

|

AMS-H-2X-12.7-*-1k-* |

12.7 ± 0.36 |

19.9 ± 0.6 |

0.68 ± 0.11 |

≤ 6.35 |

0.69 ± 0.07 |

|

AMS-H-2X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.69 ± 0.11 |

≤ 9.53 |

0.71 ± 0.07 |

|

AMS-H-2X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.71 ± 0.12 |

≤ 12.7 |

0.72 ± 0.07 |

|

AMS-H-2X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.73 ± 0.12 |

≤ 19.1 |

0.74 ± 0.07 |

|

AMS-H-2X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.75 ± 0.13 |

≤ 25.4 |

0.76 ± 0.08 |

|

AMS-H-2X-76-*-0.25k-* |

76.2 ± 0.63 |

119.7 ± 1.0 |

0.78 ± 0.14 |

≤ 38.1 |

0.79 ± 0.08 |

Table 3 - Sizes for 3X Super-Thin Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-CB-3X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.36 ± 0.10 |

≤ 0.79 |

0.56 ± 0.06 |

|

AMS-CB-3X-3.2-*-2.5k-* |

3.18 ± 0.23 |

5.0 ± 0.4 |

0.36 ± 0.10 |

≤ 1.06 |

0.56 ± 0.06 |

|

AMS-CB-3X-4.8-*-2k-* |

4.75 ± 0.25 |

7.5 ± 0.4 |

0.37 ± 0.10 |

≤ 1.59 |

0.57 ± 0.06 |

|

AMS-CB-3X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.38 ± 0.10 |

≤ 2.36 |

0.58 ± 0.06 |

|

AMS-CB-3X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.39 ± 0.11 |

≤ 3.18 |

0.60 ± 0.06 |

|

AMS-CB-3X-12.7-*-1k-* |

12.7 ± 0.35 |

19.9 ± 0.6 |

0.39 ± 0.11 |

≤ 4.75 |

0.61 ± 0.07 |

|

AMS-CB-3X-19-*-1k-* |

19.1 ± 0.40 |

30.0 ± 0.6 |

0.40 ± 0.11 |

≤ 6.35 |

0.63 ± 0.07 |

|

AMS-CB-3X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.42 ± 0.12 |

≤ 8.47 |

0.64 ± 0.07 |

|

AMS-CB-3X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.43 ± 0.12 |

≤ 19.1 |

0.42 ± 0.07 |

|

AMS-CB-3X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.43 ± 0.13 |

≤12.7 |

0.68 ± 0.08 |

|

AMS-CB-3X-76-*-0.25k-* |

76.2 ± 0.64 |

119.7 ± 1.0 |

0.48 ± 0.14 |

≤ 25.4 |

0.71 ± 0.08 |

Dimensions for tables 3 and 4

Table 4 - Sizes for 3X Normal Wall

|

Part number |

Expanded as supplied (mm) |

Recovered after heating (mm) |

|

Inside Diameter, ID |

Flat Width, W2 |

Double Wall Thickness |

Inside Diameter, Id |

Single Wall Thickness |

|

AMS-H-3X-2.4-*-2.5k-* |

2.36 ± 0.20 |

3.7 ± 0.3 |

0.44 ± 0.10 |

≤ 0.79 |

0.68 ± 0.06 |

|

AMS-H-3X-3.2-*-2.5k-* |

3.18 ± 0.22 |

5.0 ± 0.4 |

0.44 ± 0.10 |

≤ 1.06 |

0.68 ± 0.06 |

|

AMS-H-3X-4.8-*-2k-* |

4.75 ± 0.26 |

7.5 ± 0.4 |

0.45 ± 0.10 |

≤ 1.59 |

0.69 ± 0.06 |

|

AMS-H-3X-6.4-*-2k-* |

6.35 ± 0.28 |

10.0 ± 0.4 |

0.46 ± 0.10 |

≤ 2.36 |

0.70 ± 0.06 |

|

AMS-H-3X-9.5-*-2k-* |

9.53 ± 0.32 |

15.0 ± 0.5 |

0.46 ± 0.11 |

≤ 3.18 |

0.72 ± 0.06 |

|

AMS-H-3X-12.7-*-1k-* |

12.7 ± 0.35 |

19.9 ± 0.6 |

0.47 ± 0.11 |

≤ 4.75 |

0.73 ± 0.07 |

|

AMS-H-3X-19-*-1k-* |

19.1 ± 0.41 |

30.0 ± 0.6 |

0.48 ± 0.11 |

≤ 6.35 |

0.75 ± 0.07 |

|

AMS-H-3X-25-*-0.5k-* |

25.4 ± 0.45 |

39.9 ± 0.7 |

0.49 ± 0.12 |

≤ 8.47 |

0.76 ± 0.07 |

|

AMS-H-3X-38-*-0.5k-* |

38.1 ± 0.51 |

59.8 ± 0.8 |

0.51 ± 0.12 |

≤ 12.7 |

0.78 ± 0.07 |

|

AMS-H-3X-51-*-0.25k-* |

50.8 ± 0.56 |

79.8 ± 0.9 |

0.52 ± 0.13 |

≤ 16.9 |

0.80 ± 0.08 |

|

AMS-H-3X-76-*-0.25k-* |

76.2 ± 0.64 |

119.7 ± 1.0 |

0.54 ± 0.14 |

≤ 25.4 |

0.83 ± 0.08 |